Data Driven Manufacturing Processes Modelling

Title: Data Driven Manufacturing Processes Modelling

Research Area: Engineering and Business

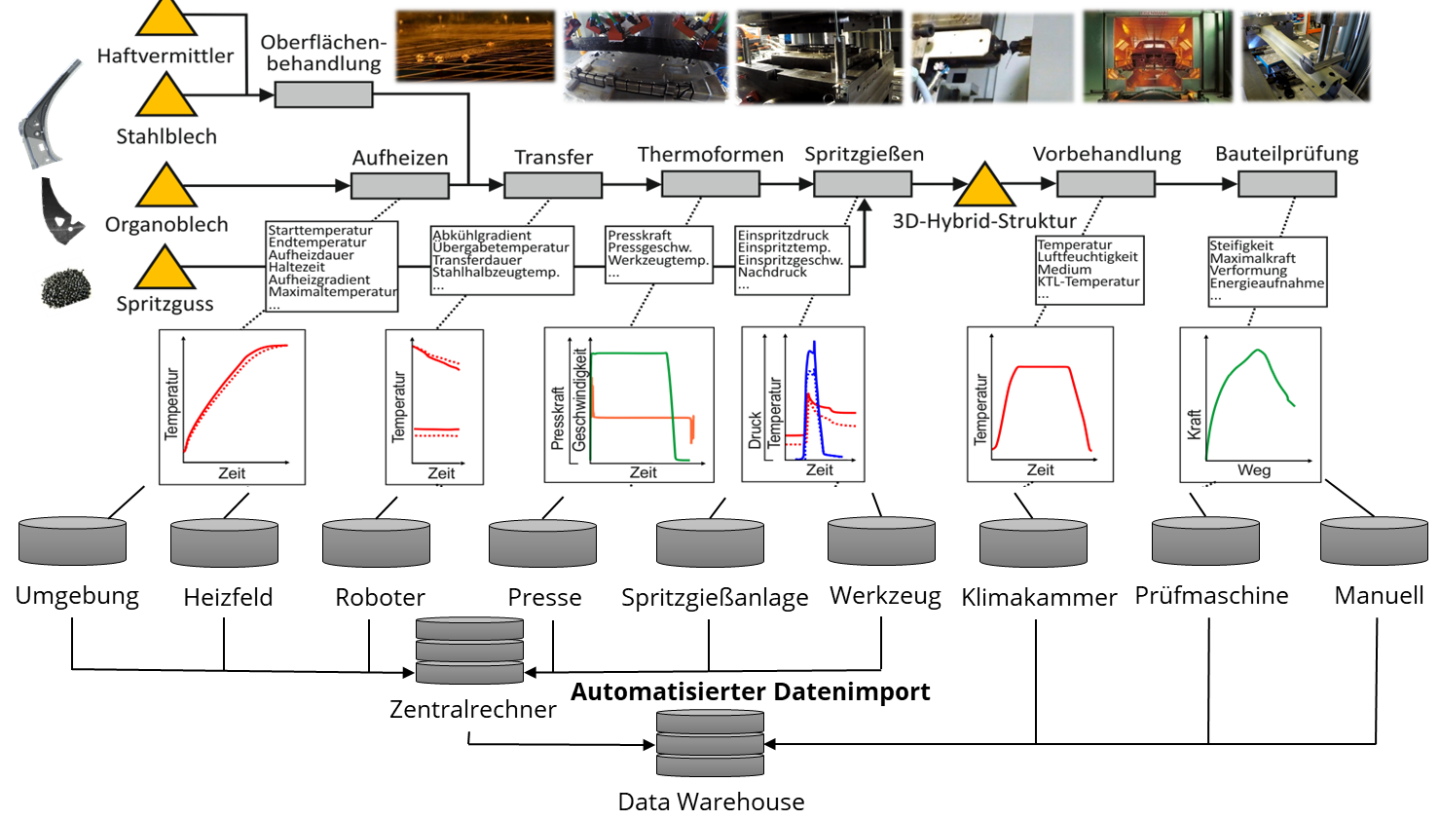

Our initiative focuses on analyzing real-world manufacturing processes through data-driven methodologies. Leveraging advanced analytics and machine learning techniques, we develop robust models to understand, predict and optimize manufacturing operations. By harnessing data from various sensors and machines along the processing steps, we aim to enhance efficiency and improve product quality. Through iterative refinement, our models adapt to dynamic production environments, driving continuous improvement and cost savings. Our collaborative approach integrates domain expertise with cutting-edge data science to empower manufacturers with actionable insights for informed decision-making and sustainable process optimization.

Aims

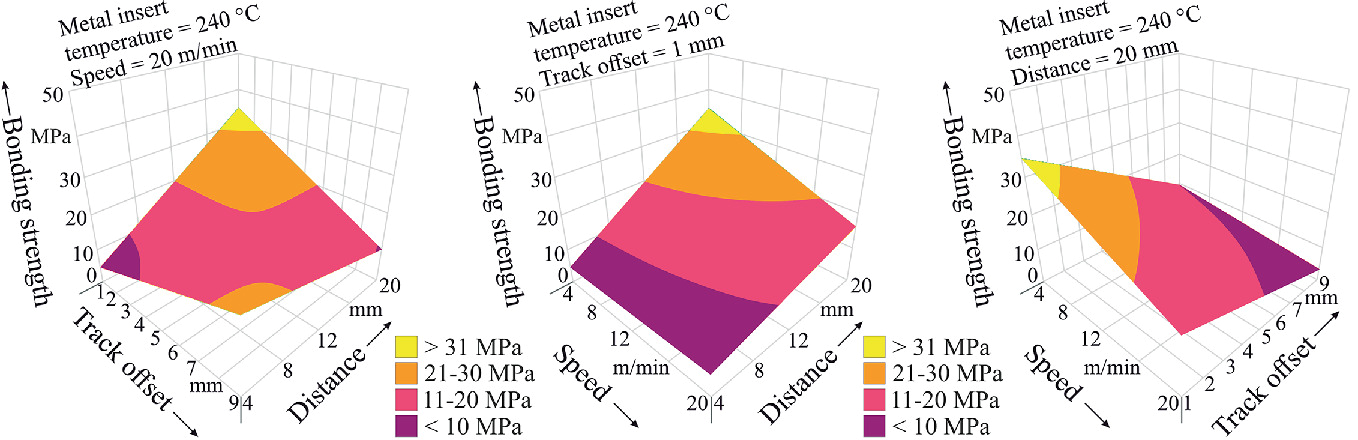

Our goal is to identify optimal processing parameters. This approach is pursued for two process chains: 1st a lab scale bonding process, in which cohesive and adhesive strengths should be maximized and 2nd a full scale manufacturing process of a hybrid A-pillar, in which energy dissipation up to a predefined intrusion limit should be as high as possible whilst preventing sharp maxima in the force-displacement curve. By employing data-driven analyses, we seek to maximize efficiency and effectiveness in the manufacturing processes while minimizing resource consumption.

Problem

We aim to elucidate the relationship between processing parameters and resultant properties in manufacturing. By analyzing data, we seek to understand how variations in parameters influence outcomes, facilitating informed decisions for optimizing processes and improving product quality.

Technology

We employ Random Forest Regression coupled with latent space modeling to analyze complex manufacturing data. This integrated approach enables us to capture intricate relationships between processing parameters and product properties, providing comprehensive insights for process optimization and predictive modeling.

Outlook

We plan to leverage model predictions for conducting manufacturing trials aimed at validating and refining our insights. By integrating predictive analytics into trial design, we aim to streamline experimentation, reduce time and resource costs, and expedite the identification of optimal process parameters. This iterative approach fosters continuous improvement and enhances the efficiency and effectiveness of manufacturing operations.

Publications

- von Unold, M., Haider, D., Gerritzen, J., Hornig, A., & Gude, M. (2019). Manufacturing of Hybrid Overmoulded FRP Components: Impact of Process and Environmental Parameters on the Mechanical Properties (Version initial) [dataset]. Zenodo. https://doi.org/10.5281/ZENODO.6607441

- TU Dresden and Citrine Informatics collaborate on fiber reinforced plastics (FRP) components research. Joint press release: https://citrine.io/media-post/tu-dresden-and-citrine-informatics-collaborate-on-fiber-reinforced-plastics-frp-components-research/

- Koshukow, W., Liebsch, A., Wippermann, J.; Kolbe, B.; Kupfer, R., Troschitz, J., Buske, M., Meschut, G., Gude, M.: (2023). Influence of Plasma Coating Pretreatment on the Adhesion of Thermoplastics to Metals. In: Proceedings of the Munich Symposium on Lightweight Design 2022. Springer Vieweg, Cham. https://doi.org/10.1007/978-3-031-33758-1_7

Team

Lead

- Prof. Dr. Maik Gude

- Johannes Gerritzen

Team Members

- Dr. Andreas Hornig

Partners