Defect Pattern Recognition in Composite Materials Based on Shearography Imaging

Title: Application of Machine Learning for Defect Pattern Recognition in Composite Materials Based on Shearography Imaging

Project duration: 2021-2022

Research Area: Engineering and Business

We demonstrate the integration of machine learning techniques for defect detection in composite materials through Shearography. Shearography is a full-field and material independent non-destructive testing method. By employing convolutional neural networks, we successfully enhanced the accuracy of identifying composite-specific defect. This innovative methodology not only streamlines non-destructive testing processes but also establishes a foundation for robust quality assurance in industries such as aviation and automotive, where composite materials play a crucial role.

Aims

The project aims to use images of shearography, a non-destructive testing method based on phase shifting and interferometry for improving accuracy and efficiency in identifying defect patterns. To ensure reliable quality assurance in critical industries we

- detect defects in composite materials

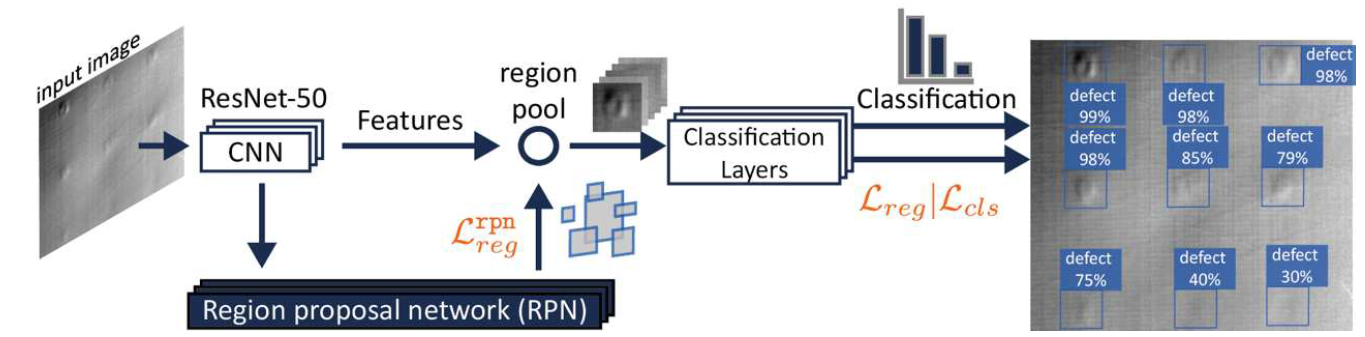

- explore capabilities of machine learning framework for object detection based on faster R-CNN with a ResNet-50 backbone

- develop an automated defect pattern recognition

Problem

The central question driving the project is how to effectively utilize machine learning, specifically convolutional neural networks, to enhance defect detection in composites.

Practical example

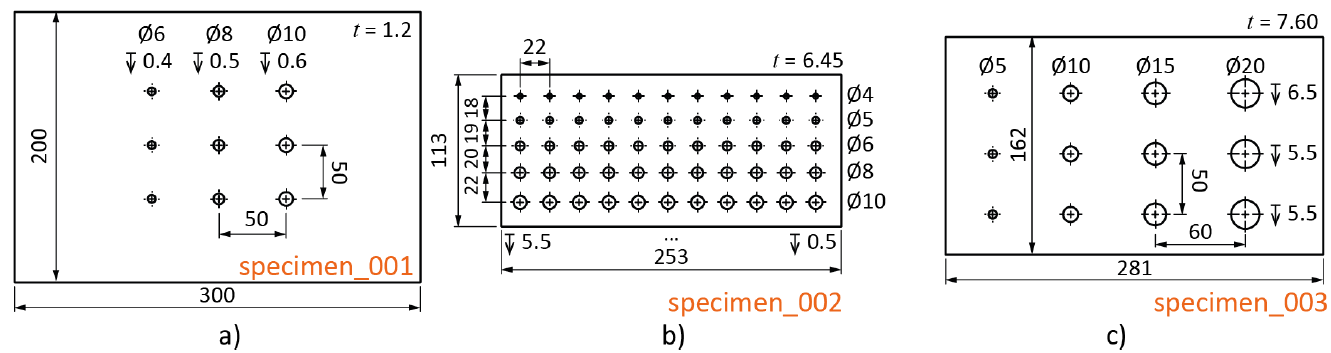

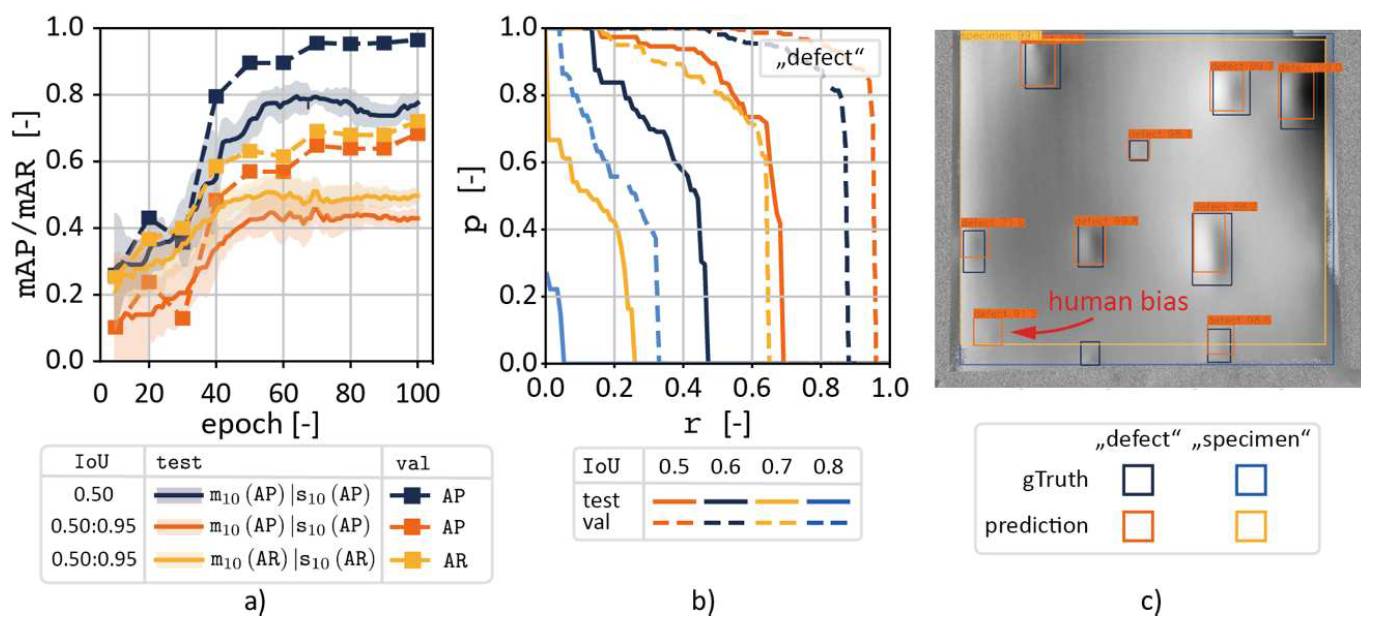

Shearographic examinations of different specimens are conducted with temporal phase shifting method to create a large data set. Thereby, different shear angles and amounts have been considered to increase the diversity of the dataset. This data set has been used to train, validate, and test a machine learning model based on a CNN with the faster R-CNN region proposal network and the pretrained ResNet-50 as backbone. Via transfer learning the model was optimized using the ADAM optimizer and training rate scheduler on the dataset of shearographic images. Using the COCO evaluation method, the model performed with a considerable mean average precision of 47.7 % and a mean average recall of 51.1 % on an unknown dataset for the intersection over union rage from 50 to 95 %.

Technology

The object detection framework faster R-CNN, which is based on convolutional neural networks (CNN), is applied to shearographic images containing different kinds of defect patterns and characteristics. This implementation uses the pre-trained ResNet-50 as a backbone for feature extraction and classification tasks. To determine the accuracy of the model the common evaluation method (COCO) was applied on an unknown dataset.

Outlook

It emerged that the relative low accuracy occurred from a high false positive rate, due to human labeling bias. Consequently, further studies and methods have to be elaborated to decrease the impact of manual annotations. Also, the transferability of the developed method into other non-destructive evaluation techniques and the usage of modelling based virtual ground truth data will be focussed.

Publications

- Düreth, C., Hornig, A., Koch, I., & Gude, M. (2022). Application of machine learning methods on the defect detection in shearographic images. In A. P. Vassilopoulos, & V. Michaud (Hrsg.), Proceedings of the 20th European Conference on Composite Materials: Composites Meet Sustainability (Band 3, S. 492-501). Ecole Polytechnique Fédérale de Lausanne (EPFL). https://doi.org/10.5075/epfl-298799_978-2-9701614-0-0

- Düreth C (2022) ShearDetect – Dataset (Version 1.1). Zenodo. https://doi.org/10.5281/zenodo.6463119

Team

Lead

- Prof. Maik Gude

Team Members

- Christian Düreth

- Ilja Koch

- Dr. Andreas Hornig

Partners