Advancing Failure Analysis in Fibre-reinforced Plastic Materials

Title: Advancing Failure Analysis in Fibre-reinforced Plastic Materials

Duration: ongoing

Research Area: Engineering and Business

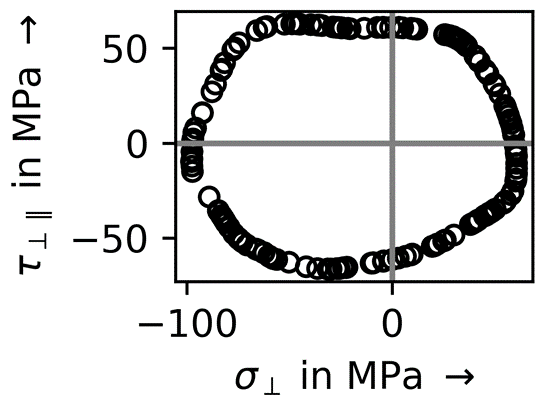

The failure behavior of fiber reinforced plastics (FRP) is highly dependent on the specific loading conditions. A multitude of concurrent failure modes contribute to final failure. Established theories allow an accurate assessment of stress states in the plane of fibers. They however, oftentimes lack generalizability to 3D stress states; in part due to the fact that generally such stress states cannot be analyzed in an isolated manner by experiments. We therefore employ a scale bridging approach of modeling the FRP on a microscale, taking into account fiber distribution and nonlinear matrix behavior. Failure is predicted by means of finite element analysis and corresponding stress state and failure mode automatically extracted. Various machine learning algorithms are investigated with regard to their capability of predicting this failure information. This leads to an machine learning based failure envelope that represents arbitrarily complex stress states equally well.

Aims

Our goal is to enhance the predictive capabilities of material models for fiber reinforced plastics (FRP) with special focus on the failure behavior. Taking complex 3D stress states into account for the definition of the failure envelope, allows a more realistic assessment of real world structures under actual loading conditions. Given more a more reliable failure prediction, current safety margins can be cut back and thus material can be saved, leading to a twofold increase in resource efficiency: direct in terms of used materials for a component and indirect by reduction of energy necessary for moving such parts.

Problem

Current failure theories for unidirectionally fiber reinforced plastics (FRP) are motivated by and largely tested under plane stress conditions. With the growing application of FRP in complexly loaded components, this assumption no longer holds. Since arbitrary 3D stress states generally cannot be investigated in experiments in an isolated manner, numerical simulations offer an invaluable possibility, of analyzing such states.

Practical example

The developed methodology is advanced in ongoing research projects, focusing on mechanical joining of FRP (TRR285) and the efficient digital dimensioning of hydrogen tanks for the automotive sector (DigiTain).

Technology

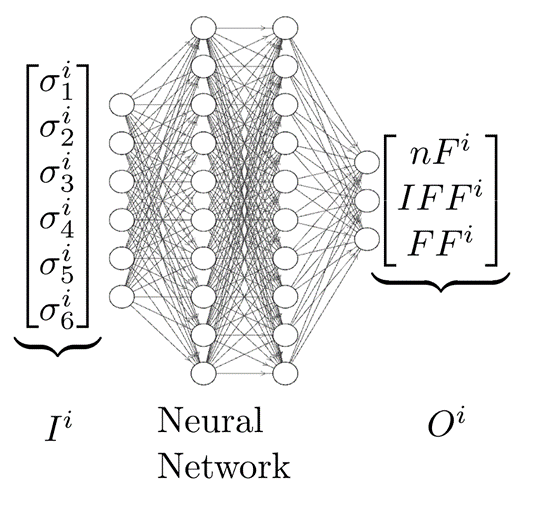

In order to generate the artificial training data, the commercial finite element software LS-DYNA is used. Representative volume elements (RVE), capturing the geometric intricacies on microscale are subjected to deformation states, defined by a space filling DOE algorithm. Information regarding failure within the RVE is extracted and used as training data. The final failure envelope is modeled as feed forward neural network.

Outlook

The developed methodology will be further developed in order to capture not just total failure of fiber reinforced plastics (FRP) but also irreversible changes in the material up to that point. This will include history dependent phenomena such as plasticity and continuum damage. In order to accurately capture this history dependence, a special focus will be on recurrent machine learning methods.

Team

Lead

- Prof. Maik Gude

- Dr. Andreas Hornig

Team Members

- Johannes Gerritzen

Partners